More Versatility Instead of Idle Time

What happens to open wagons that are no longer needed for their original function? The answer is upcycling. OpenBox Railway enables the retrofit of a high-quality cover system that opens up entirely new fields of application – for example, for more sensitive bulk goods or weather-dependent transports. This turns decommissioned freight wagons into versatile specialists. Retrofitting saves resources and extends usability – without the need for new construction.

Cover Technology with Tangible Efficiency Gains

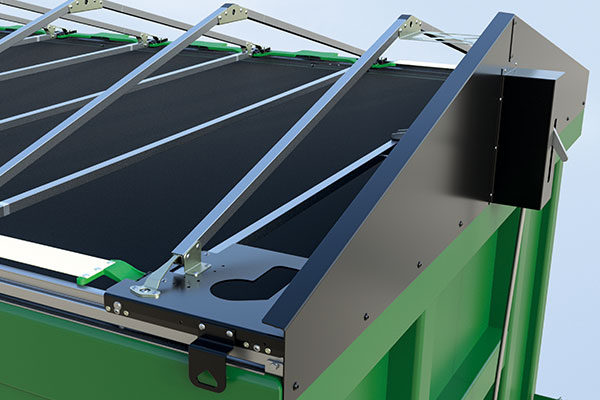

The complete integration into the wagon structure enables sealed, weatherproof, and operationally safe transport. The new bow construction ensures both stability and effective drainage. A closed roof not only reduces the risk of load loss – it also improves aerodynamics. Particularly during empty runs, this significantly reduces energy consumption and required traction power. Here, sustainability is not an afterthought – it’s the foundation. OpenBox Railway delivers not just new technology, but a new mindset for rail freight.

Safety and Ease of Use from the Ground

Covering used to be strenuous manual work. Now, it takes just one easy movement from ground level: the system operates smoothly, is safe to use from the ground, and can be opened or closed in very little time. The newly developed locking mechanism works reliably on both sides – even with older wagons that show slight structural deformation.

Robust and Retrofit-Ready by Design

Thanks to a floating rail that compensates for up to 60 millimeters of deformation, the system remains fully functional even on older wagons. A newly designed rigid end wall and robust steel rails with replaceable segments ensure long-term durability and ease of maintenance. Weighing only around 300 kilograms over ten meters, the entire system is ideal for retrofit projects. The optional E-Drive system further underlines the forward-thinking nature of this solution.

Existing Certification Remains Valid

One key advantage: existing certification of the category E wagon remains valid even after retrofitting with OpenBox Railway. This eliminates the need for costly recertification – a clear operational benefit. TÜV (German MOT) has confirmed compliance with standards EN 283 and UIC 596.

When Technology Becomes Environmental Protection

Upcycling is not just a technical choice – it’s an ecological one. Reusing existing freight wagons conserves resources and reduces emissions. OpenBox Railway is thus an investment in both the economic and environmental sustainability of rail transport.

A Second Life for Old Wagons

OpenBox Railway proves how retired open wagons can be turned into modern, high-performing cargo carriers. Instead of disposal, there’s added value – through intelligent technology, practical handling, and lasting impact. This is how the past is put back on track – toward a sustainable future.